November 1, 2010

This article is based on information gethered from presentations given at this year's SAE OBD II Symposium. On-board diagnostics (OBD) is on the cusp of major architectural change. The sheer volume and complexity of data being communicated is one key driver. Moving that data faster is another. As a result, the limited data transfer speed and bandwidth of controller area network (CAN) architecture could be overwhelmed in just a few years. Internet Protocol based replacements are now under development, most notably Ethernet. When implemented, scan tool manufacturers and service/repair facilities will be impacted. The regulation of emissions, vehicle complexity, functionality, telematics, safety and worldwide harmonization are just some of the factors causing a surge in the amount and nature of data that is communicated. Not only is the volume of data going vertical, it is also becoming richer in nature. It’s also important to note that OBD is not limited to emissions only. Telematics, in-vehicle multimedia content, performance upgrades, emerging complex safety systems and other applications are driving OBD into nonemission areas, a field known as enhanced OBD.

There’s an app for that! For an example of the fragmentation, consider these two divergent paths. Ford has announced they are developing an application program interface (API) that will allow developers to create applications for smart devices that can be controlled through its Sync system’s voice and steering wheel controls. Continental’s AutoLinQ plans to distribute a open-source operating system software development kit (SDK) that will allow developers to create automotive specific applications for android-based platforms only. But here’s the rub. Ford’s approach is more universal, as it will enable developers to interact with the vehicle from multiple smart device platforms regardless of operating system; the Continental approach, while not as universal, potentially provides better integration between the vehicle and the apps. Why not combine the best of both approaches, if proprietary safeguards could be assured? Research firms say that telematics is still in its infancy and that the automotive telematics market is poised to get even more crowded. For instance, Frost & Sullivan expects the telematics market to grow from $80 million annually in 2008 to over $700 million by 2015. Another consultant, ABI Research, projects that the 37 million telematics users in 2010 will climb to over 211 million by 2015. In addition, the nature of telematic content is broadening and getting richer. Moving that data requires increasing bandwidth.

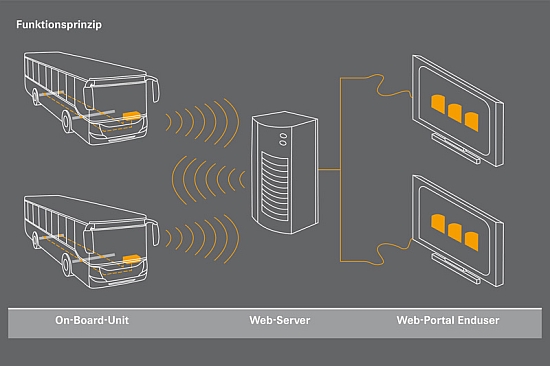

Moving towards a common, compatible solution “The end-user wants a single solution” claims Thomas Rösch, director of ZF’s Openmatics business unit, which is set to begin operation in January 2011. “Openmatics provides the means to integrate multiple telematics stand-alone applications. It will turn competitors into partners. The idea is to develop and offer Openmatics apps for OBD and the delivery of other telematic products and services.” He adds that the concept is similar in nature to how apps are developed by many providers and then delivered universally to personal devices (e.g. smartphones, tablets, in-vehicle systems, etc.). Vehicles would have a single ‘on-board unit’ (OBU) and a software platform, which will cover all telematics services and products. Using APIs and SDKs to protect their competitive advantage, Rösch says providers can freely develop their own apps, which can be deployed universally to any smart user device, and they can set their own prices. Data security and separation are a top priority: App providers will be able to define user-groups and determine the level of access within the app. Openmatics also takes care of payment processing between users and providers, as well as any further handling of the app. Consider the potential, positive impacts on the automotive industry.

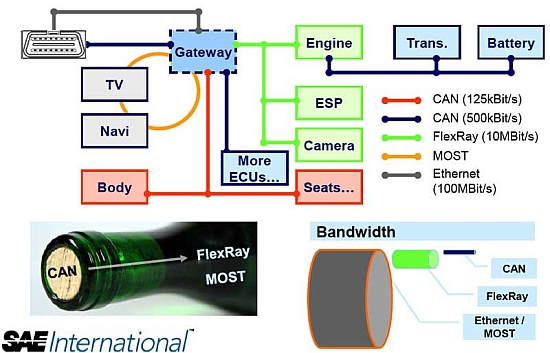

CAN is becoming a bottleneck CAN’s lower data transfer speeds and smaller bandwidth results in a communications pipeline that is too constricted to manage the complexity, high volume and rich nature of data today. For instance, CAN transfer speeds are typically between 125,000 and 500,000 bits/second; in contrast, Flexray offers 10 million bits/second, Media Orientated Systems Transfer (MOST) typically offers 50 and 75 million bits/second, while Ethernet delivers 100 million bits/second or more. Factor in the bandwidth attribute for each, and CAN is once again dwarfed by Flexray and MOST, which in turn, have narrower bandwidth than Ethernet. Functionality and interdependence continues to ramp up as modern vehicles feature an evolving mix of automotive systems, consumer infotainment and comfort systems. In addition, these emerging features and functions require increased memory capacity, faster data transfer rates and wider bandwidth communication networks than CAN is able to provide. Engine control units (ECUs), for example, are used for multiple interdependent applications today. “This is a world where the ECU is a protocol machine,” Saalfeld explains. “It implements several different communication protocols to observe OBD data, which can be emissions-related diagnostics or concerned with enhanced diagnostics (related to non-emission aspects for performance, comfort or amenities).” This increased functionality means that modern ECUs require more memory and quicker data transfer. Even building the gateways (i.e. interfaces) to connect various communication networks in vehicles requires space, weight and dollar considerations that could be better used elsewhere.

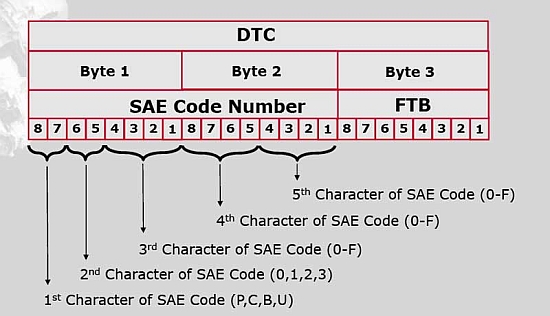

An interim step provides breathing room Automakers typically employ one protocol specification for emissions diagnostics only, while a different

specification is used for enhanced (non-emission) diagnostics. Saalfeld says there is a strong interest in the

short term for using the same protocol specification for all OBD, whether emissions-based or otherwise. UDS over CAN architecture employs an ISO15031-compliant three-byte (i.e. 24-bit) diagnostic identifier, comprised of a two-byte (16-bit) Diagnostic Trouble Code (DTCs) and a one-byte Fault Type Byte or Fault Mode Identifier. Switching from emissions-based OBD to UDS over CAN OBD messages offers several advantages. For example, UDS over CAN:

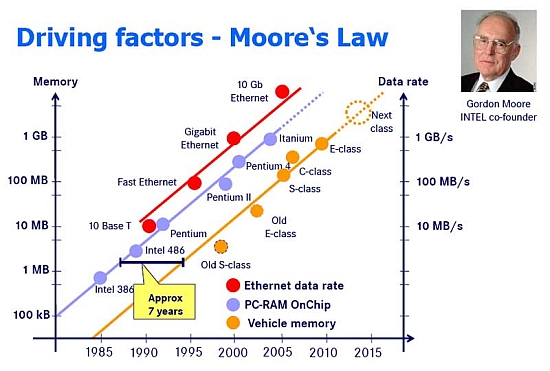

Ethernet will be the game-changer Moore's Law, developed by Intel co-founder Gordon E. Moore, states that the number of transistors that can be placed inexpensively on an integrated circuit has doubled approximately every two years. Vehicle electronics and computerization follow computer chip development by a lag of seven years,” notes Saalfeld. The lag between the two industries provides both security, surety and efficacy benefits for the automotive industry. Due to the bandwidth and data limitation of CAN, Flexray and MOST, Saalfeld believes that over the long term, Ethernet will become the dominant communications system for OBD. “Imagine you have a CAN connection to your gateway [interface] and then after the gateway, you have a Flexray BUS,” Saalfeld suggests. “If you want to flash reprogram the ESP, a camera system or an engine retooler, you may not be able do this because the CAN slows you down or stops you cold.” The computer industry has already developed well-established standards and in-market product experience in debugging software glitches that typically occur early after product launches. On the one hand, this would require OEMs and scan tool manufacturers alike to abide by computer world rules, not just auto industry rules. On the other, the lag allows adoption of proven technology into vehicle applications. Besides already having well-established standards, Ethernet connections can handle more data as it has a higher data transfer rate and bandwidth. Ethernet has huge market penetration across a number of industries. Simply put, it works. Ethernet technology is also backwards compatible — new Ethernet technology can accommodate older verisons. In addition, the explosive growth of telematics is tethered to increasing bandwidth. Current in-car telematics technologies are limited by low bandwidth. Ethernet’s increased bandwidth advantage will provide opportunities to leverage richer, more disparate data to significantly increase the interaction between the in-vehicle technology and the outside world. Apps will evolve in tandem with the increased bandwidth. Saalfeld acknowledges that some Ethernet-related concerns need to be resolved while there is time. The 2008 exclusive mandate granted to CAN architecture has to be revisited. Developing and utilizing shielded Ethernet cables to prevent electromagnetic interference is one area. Collaborating to adopt common, compatible standards to avoid redundant duplicity is another. Finalizing a shape for automotive Ethernet connections that are distinct from consumer products is another safeguard the industry has to address, as is ensuring the security. But even with these hurdles Saalfeld concludes, “The Ethernet is the future for vehicle OBD.” ### |

Full Members of ETI:

Registration is now open for Winter Tech Week.

When: December 6-9, 2010

Where: Tokyo, Japan

Click here for more info and registration.

You can now purchase copies of ETI's Market Research Survey Reports on Flash Reprogramming, TPMS and Telematics. Click Here for more information.

| Regular Features

Feature Stories

Other Links

|

Copyright © 2010 - All Rights Reserved

Industry Update - is produced by the Equipment and Tool Institute, Inc.

Statements of fact

and/or opinions expressed are the responsibility of the authors alone and do not imply an

opinion of their officers, directors or members of ETI. Segments in their entirety may be

reproduced provided ETI Industry Update is credited as the source.

Equipment & Tool Institute

134 W. University Dr.

Suite 205

Rochester, MI 48307

PHONE 248-656-5080

FAX 603-971-2375

By Bob Chabot, Contributing Editor

By Bob Chabot, Contributing Editor