By Bob Chabot, Contributing

EditorETI Hosts NASTF General MeetingParticipation by ETI members helps move NASTF forwardETI hosted the National Automotive Service Task Force (NASTF) Spring General Meeting, themed “Improving Communication and Awareness” on May 2 during ToolTech 2011. The meeting consisted of a business meeting and panel discussion, both of which saw participation by ETI members. A full report of the NASTF general meeting can be viewed at the NASTF website, but a condensed recap of points and business opportunities relevant to ETI members follows.

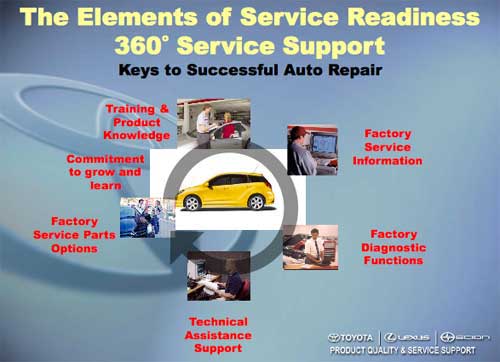

Here is a brief recap of the key insights that were provided by the participants, a number of whom represent current ETI members: Theft-related vehicle service information and parts are being securitized — Mary Hutchinson, NASTF administrator, shared that automakers are beginning to view NASTF’s Secure Data Release Model (SDRM) as a viable means of providing vetted aftermarket service/repair facilities with security- and theft-related parts and service information, without compromising original equipment manufacturer (OEM) proprietary information or vehicle owner’s privacy. Mercedes Benz USA has been piloting this in the United States, and is now expanding the number of parts available through the SDRM. Hutchinson also shared that NASTF is working with the Canadian service/repair market to enable the SDRM to be used in the Canadian aftermarket. The awareness of NASTF and its purpose is growing — John Lypen of MOTOR Information Systems (an ETI member), and the publisher and editor of MOTOR Magazine, presented the results of a survey that showed that 27 percent of aftermarket service/repair shops surveyed were aware of NASTF and its purpose. While pleased with the awareness level, NASTF board members want to grow awareness to higher levels across all industry segments. Heavy-duty vehicle business opportunities exist — Carl Kirk, the American Trucking Association vice president for maintenance, information technology and logistics, discussed the potential for industry collaboration that could help the heavy-duty industry meet mandated emissions regulations that begin in model year 2013. He cited access service information as well as improved tools and equipment as two needs of the heavy-duty vehicle segment. ETI and NASTF are building a meaningful scan tool database and working to close tool information gaps — Greg Potter, of DG Technologies (an ETI member), serves as co-chair of the NASTF Tool and Equipment Committee. He reported that this Committee is nearing completion of an OE Tool Matrix that would enable service/repair professionals, before they purchase a tool, to compare feature sets of available tools in the matrix to their needs. The Committee is also liaising with ETI on two initiatives — (1) Using ETI as a pathway to closing OEM tool, service and training information gaps; and (2) Encouraging tool and equipment makers to use the NASTF Service Information Request (SIR) process to document, identify and resolve these gaps. Improving communication takes genuine and active collaboration — “Collaboration can benefit OEMs, Tier 1 suppliers, and the independent aftermarket in a number of ways,” explained Shuvo Bahattacharjee of Bosch ETAS, a business unit of Robert Bosch LLC (an ETI member). “For example, standardizing a format for data exchange for tool manufacturers could help simplify vehicle diagnoses, enable key OEM intellectual property to be protected, improve the exchange of vehicle failure data over longer cycles, foster the development of new methods for prognostics and predictive diagnostics and reduce legislative-driven requirements — all of which would vastly improve the customer's brand experience.” Improved communication and common open standards could help reduce diagnostic tester development costs — “There's lots of parametric data, in many various forms, across many vehicle makes and models, that requires a high effort to effectively manage,” stated Bernie Carr, of Bosch Diagnostics, another Robert Bosch LLC business unit. “Administering this data creates a huge cost challenge for businesses.” Carr also shared that aftermarket toolmakers want to partner with OEMs. "If OEM and tool companies could create and utilize a ‘Generic Data Template (GDT)’ for tool data, OEMs could output their data in the GDT format that any toolmakers could then extract then optimize for their customers.” He also agreed that this kind of collaboration could lead to “smart” tablets or other devices serving as platforms for service information and diagnostic tools for future service and repair professionals.

The next NASTF general meeting will be held on Oct. 4, 2011 in Orlando, Fla., during Automotive Service and Repair Week (ASRW). |